Pre-engineered robotic welding systems offer a faster path to automation for companies just starting with welding automation or those whose applications fit proven configurations.

Key advantages of pre-engineered systems:

Pre-engineered systems work well when your parts and processes fit within standard system capabilities and you want to start benefiting from automation as quickly as possible.

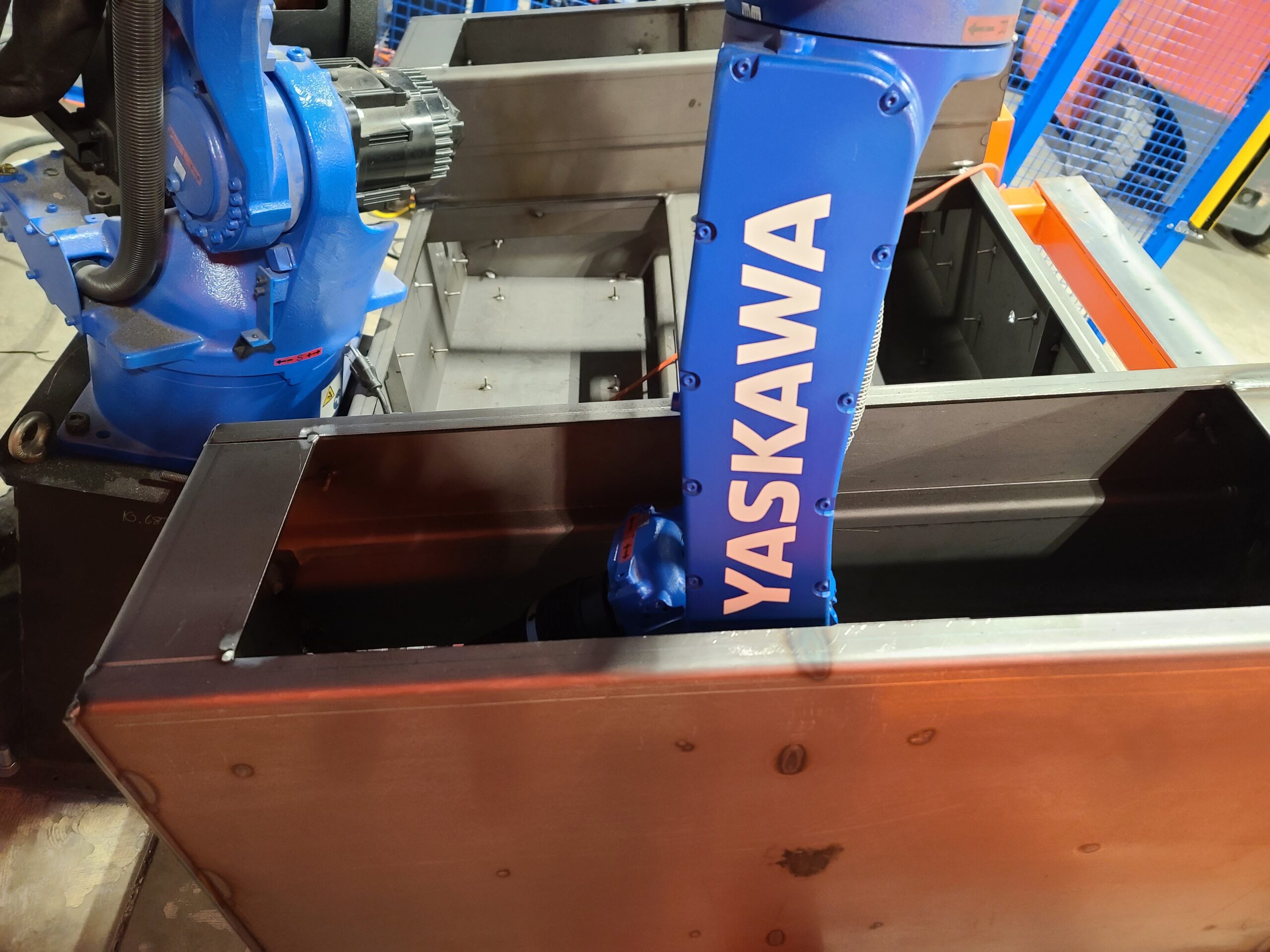

The Mach 2000 represents the next step up from entry-level automation. This intermediate pre-engineered system includes increased safety systems and an advanced controls package that provides more functionality than basic automation cells.

The Mach 2000 features more complex positioning systems that can handle a wider variety of part sizes and orientations. The enhanced safety systems and better controls make it suitable for more demanding production environments where you need additional capability but don’t require full custom engineering.

This system bridges the gap between entry-level automation and custom solutions, offering enhanced performance while maintaining the speed and cost benefits of pre-engineered designs.

The ArcWorld series includes the ArcWorld 500, 1000, and 2000 models—standardized, ready-to-deploy systems designed for companies new to welding automation. These entry-level systems provide a straightforward introduction to robotic welding without the complexity of custom engineering.

Each ArcWorld model is built around proven configurations that work for common welding applications. The standardized design means faster delivery and installation compared to custom systems. These systems include the basic components needed for automated welding while keeping the investment manageable for companies taking their first step into automation.

The ArcWorld series is ideal for manufacturers who want to test robotic welding capabilities or automate straightforward applications without the time and cost investment of custom engineering.

Mach Machines is a welding-focused robotic integrator that empowers metal fabricators with automation solutions and the technology to program and control their own production independently. We specialize in making welding automation accessible to fabricators of all sizes, whether you’re starting with a pre-engineered system or need a fully custom solution.

Our pre-engineered systems include the same programming independence focus as our custom solutions. You get the VC Robotics OLP software tools to control your own automation rather than staying dependent on integrators for ongoing programming needs. This approach gives you complete control over your production schedules and the ability to adapt quickly to new jobs.

Our complete automation solutions include:

Pre-engineered systems offer the fastest path to welding automation benefits. Contact us to discuss which system fits your application and timeline.

ArcWorld systems are entry-level automation designed for companies new to robotics. Mach 2000 is an intermediate system with increased safety systems, advanced controls, and more complex positioning capabilities for more demanding applications.

4460 Lake Forest Drive, Suite 210

Cincinnati, Ohio 45242

© 2025 Mach Machines