Pre-engineered robotic welding systems work great for many applications, but some projects require custom engineering. You might need a custom solution if your parts are too large, too varied, or too technically challenging for standard automation approaches.

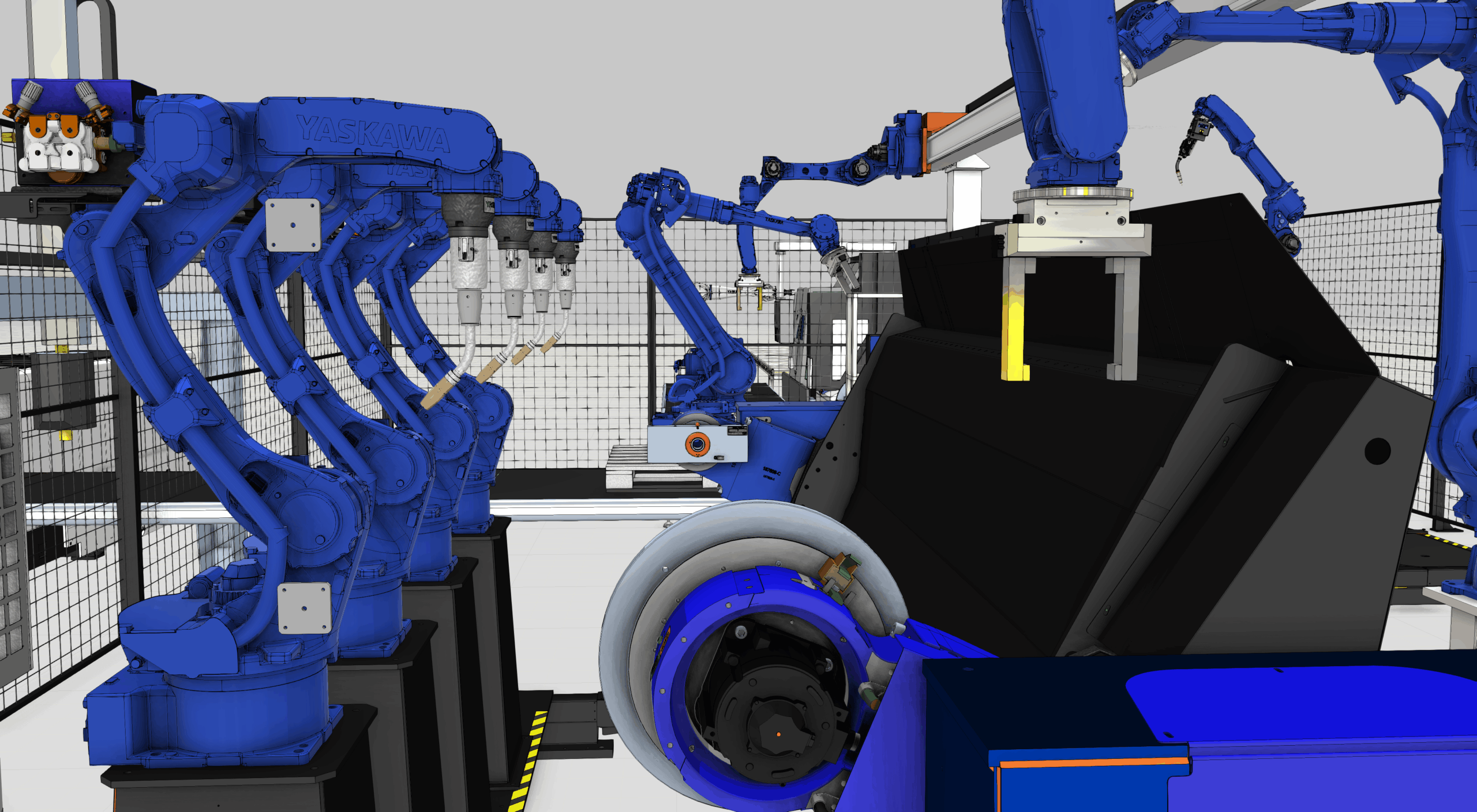

Large parts, like dump truck bodies, create size and reachability constraints that pre-engineered systems can’t handle. Multi-robot applications need specialized coordination and programming that go beyond standard cell capabilities.

If other integrators have told you “that can’t be done” or walked away from your project, you probably need custom engineering. Mach Machines specializes in the applications that others turn down.

We design systems around your specific needs rather than trying to fit your application into a standard package. Each custom system is fully engineered for your parts, your workflow, and your production requirements.

Our gantry systems handle large parts that require extended reach and positioning capabilities. These overhead structures provide the access needed for welding oversized assemblies.

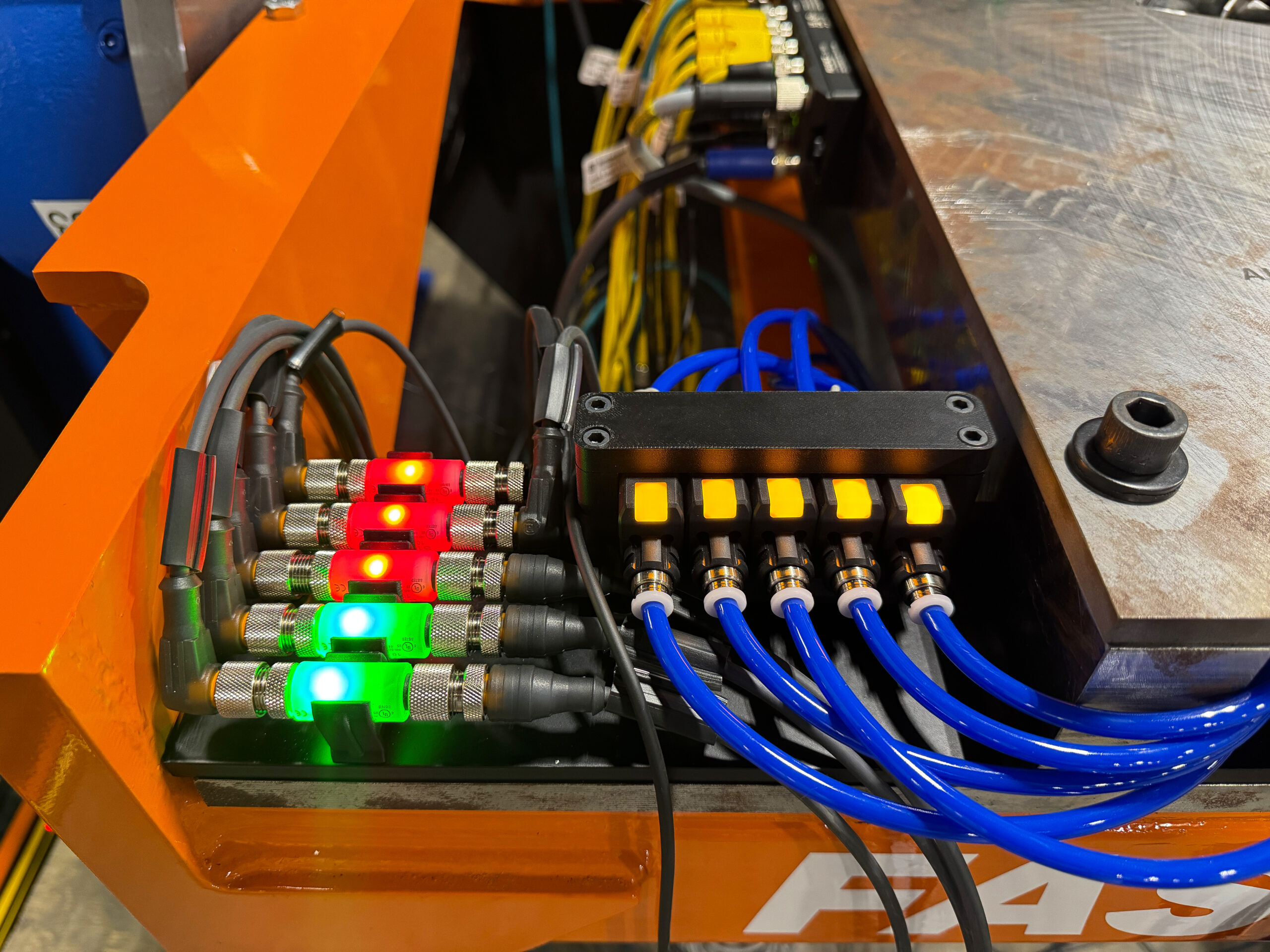

Our Server Robot technology shines a line laser onto the weld joint and keeps the robot aimed at the seam. This Powertrack system handles material movement and warping that occurs during welding.

Coordination

We program and coordinate multiple robots working on the same part or in the same cell. Our systems handle the timing and synchronization needed for multi-robot applications.

Custom robotic welding systems require complete project partnership, not just equipment delivery. We handle every aspect from initial concept through ongoing support, staying involved long after other integrators would have moved on to their next project.

We perform feasibility studies to determine if your parts can be successfully automated. Digital twinning creates a complete 3D simulation of your system before we build anything, identifying potential issues early in the design process. We handle fixture design and integration as part of the complete system solution.

We install complete working systems, not just equipment. Our installation process includes:

Cut pipe, domes, tank heads, bevels, or any complex surface with Hypertherm’s latest XPR series HD plasma systems.

Innovative custom engineered work holding solutions for unique robot applications

Mach Machines is a welding-focused robotic integrator that makes advanced automation accessible to fabricators of all sizes. While most integrators are generalists trying to serve every industry, we specialize in welding automation and understand the specific challenges that come with automating welding operations.

Our approach centers on giving you programming independence and complete control over your automation systems. We don’t just solve your immediate automation challenge—we equip you with the tools and knowledge to maintain and expand your capabilities as your business grows.

Whether you need a custom solution for an application others have turned down or an entry-level system to get started with automation, we have the expertise to make it work for your specific situation.

Besides custom robotics systems, our solutions include:

4460 Lake Forest Drive, Suite 210

Cincinnati, Ohio 45242

© 2025 Mach Machines